Panther

We are 35 year old Indian manufacturers of CNC Metal Plate Profile Cutting Machine by model name: Panther.

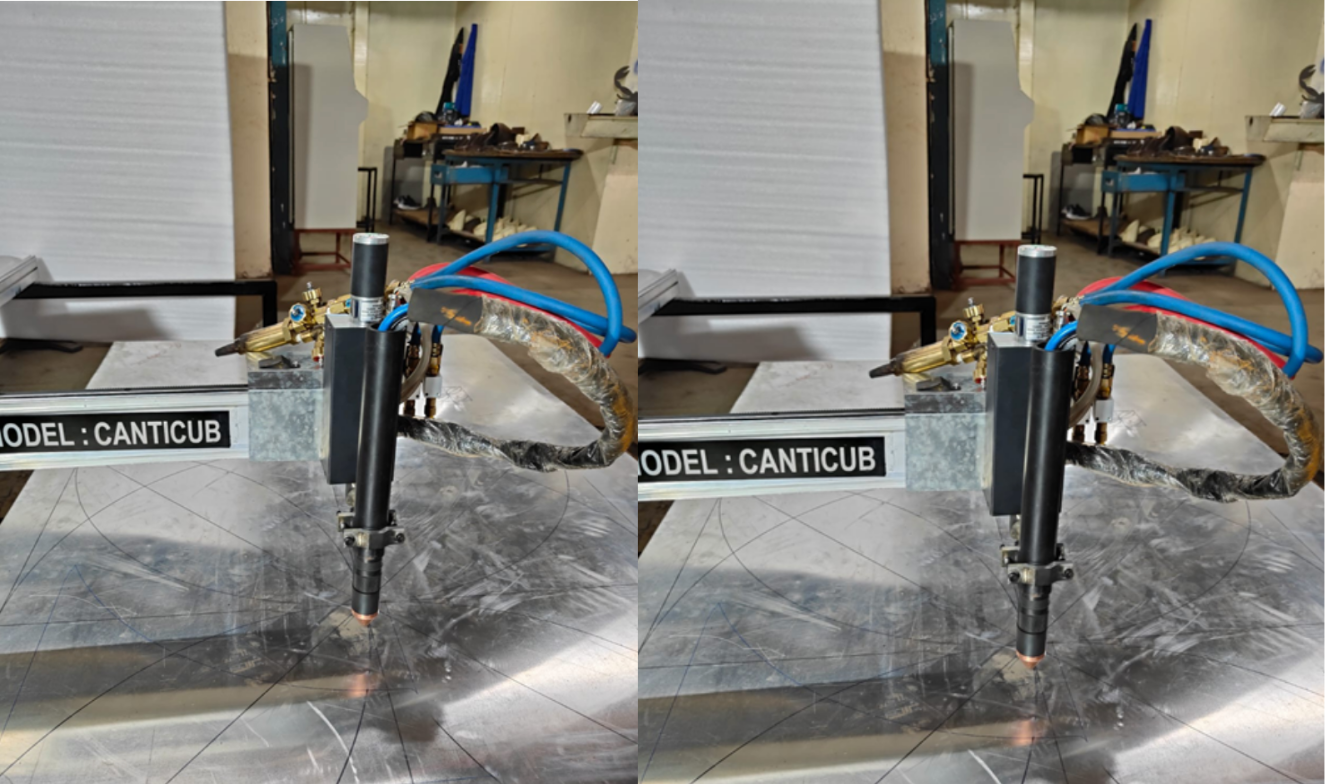

Panther model essentially is a Gantry type single / dual drive CNC machine used for profile cutting applications for metal by using either Plasma torch or OxyFuel or both. If Air Plasma is used for cutting, then Plasma Power Source also is provided. If OxyFuel profile cutting method is used then OxyFuel cylinder bank at site is utilized. We also offer “L” series which is Lite version which comes with basic features with / without cutting bed, but with controllers, hardware’s, motors drives, software & drag chain for cables etc. Fully loaded machine can come with capacitive auto height controller attachment, Auto Torch Igniter for OxyFuel cutting torch and Initial Height Sensing & Auto Height Controller model PMT for Plasma Torch with / without fume extraction table as accessories.

Typical Customer Requirement:

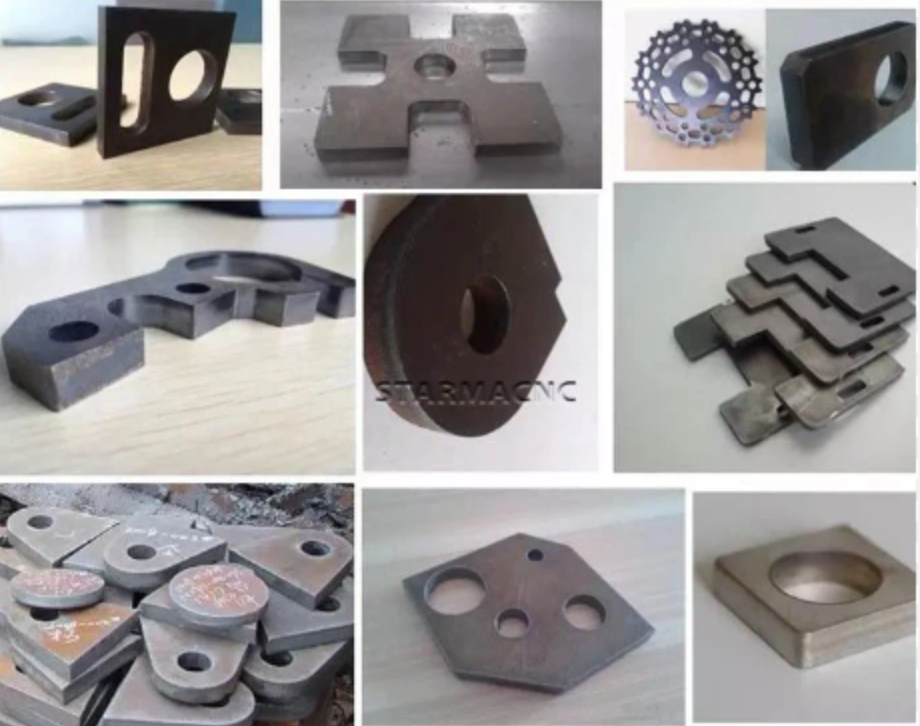

| Material MS | 1mm to 150mm with Oxyfuel Torch |

| Material SS | 1mm to 50mm |

| Plate Length | 12.5mtr |

| Plate Width | 2.5mtr |

Technical details:

| Type of machine | Gantry CNC |

| No of torches | 2 Nos. (1 No. Plasma & 1 No. Oxy Fuel) |

| Working area | 12.5 m x 2.5 m |

| Machine area | 13.5 m x 3.3 m |

| Plasma Source | 300 amps Model HyCUT 300 |

| Cutting capacity with Plasma | Piercing – 38 mm Edge cutting – 50 mm |

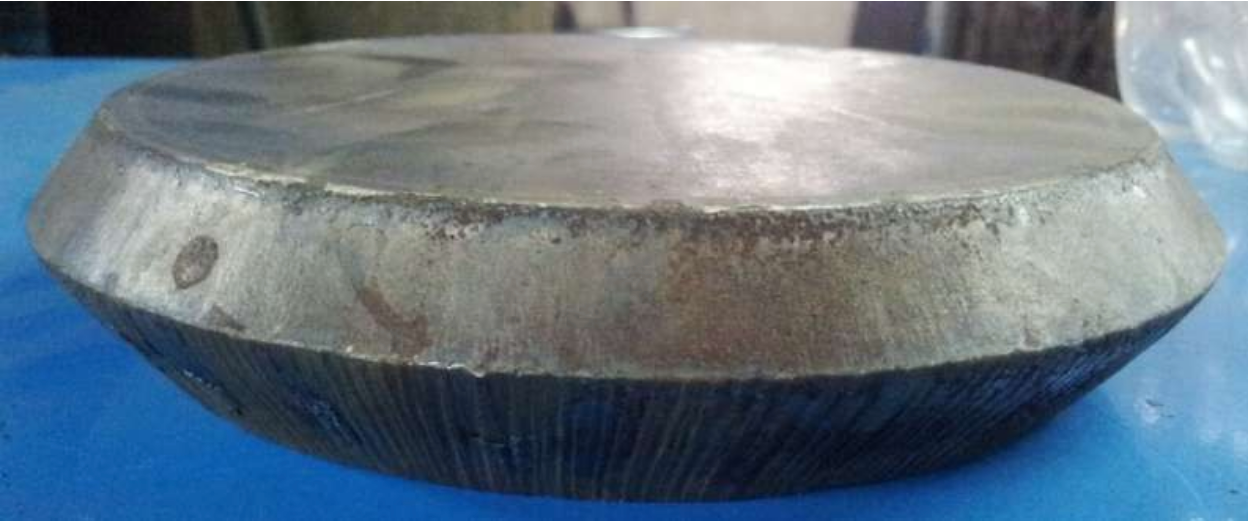

| Cutting with Oxyfuel (maximum) | 200 mm |

| Structure material | Hardened and ground rail, specially designed guides, MS Frame |

| No. of controlled axes with independent drives | X axis- 2 nos. Y axis- 1 no. Z axis- 1 no. |

| Drive mechanism | Rack & pinion for X1, X2 and Y axis Ball screw for Z axis |

| Rapid speed | 12 mtrs. /min |

| Height control | Initial Height Sensing & Auto height control (For Plasma) Automatic torch height control through Capacitive Height Control (For Oxy Fuel) |

| CNC controller make | FLMC / equivalent |

| Cable conveyors | Cable drag chain system |

Critical items and make:

| Sr. no | Description | Make |

| 1 | Rack | KHK or Equivalent |

| 2 | Pinion | Technocrats |

| 3 | LM guides | Hiwin |

| 4 | Gearbox | Delta or Apex or Sesame |

| 5 | Controller | FLMC or equivalent |

| 6 | Servomotor & drive | Delta or Panasonic or equivalent |

| 7 | Arc voltage torch height control | Technocrats |

| 8 | Plasma Power Source | Technocrats |

| 9 | Oxy Fuel Torch | Longteng / Harris / TANAKA |

| 10 | Capacitive Height Controller | HYD |

| 11 | Limit switches | Teknic |

| 12 | Relay card | Omron |

| 13 | SMPS | Meanwell |

| 14 | Cables | Polycab / Finolex/ LAPP |

| 15 | Relays | Omron/ PLA |

| 16 | Cable Drag chains | IGUS/ Teknic |

| 17 | Nesting software | Most 2D / CAD CAM |

Plasma source details – HyCut 300

| Plasma source type | IGBT type |

| Model | HyCUT 300 |

| Current range | 30 – 300 amps |

| Maximum output power | 60 kW |

| Torch cooling | Water cooled |

| Cutting capacity | Piercing – 38 mm Edge cutting – 50 mm |

General requirements for installation at site:

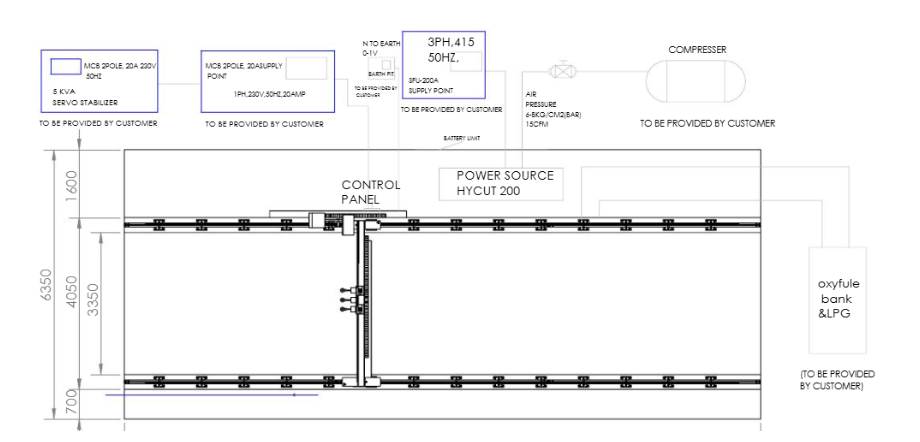

1.Servo Stabiliser

2.Computer Requirements:

a.Minimum Windows 10 to support Nesting software.

3.Operator Requirements:

a.Working knowledge of AutoCAD, Computer skills, and the English language.

4.Power Supply:

a.Three-phase, 415V AC, 150 AMPS supply point with a 3-pole SFU for plasma power source.

b.Single-phase, 230V AC, 20 Amp supply point with a 2-pole SFU for CNC machine.

5.Air Compressor:

a.Clean & dirt-free air delivery at 6-8 kg pressure with a dryer unit.Specifications:

b.Two-stage head (2 cylinders).

c.Tank capacity: 200 liters.

d.Cfm: 13 CFM (FAD).

e.3-phase, 5 hp motor.

6.Civil Foundation/Structure:

a.Depending on standard civil foundation or structure fabrication, we can send the final GA drawings accordingly.

7.Anchoring:

a.Chemical Hilti bolts M16x150L - 130nos (as per site arrangement), considering the RCC flooring.

8.Earthing:

a.Separate Earthing pit with neutral to Earth 0-1 volt.

9.Oxyfuel System:

a.Customer arranges oxygen cylinder bank and LPG cylinders with proper manifold block for continuous operation.

10Unloading and Storage Requirements:

a.To ensure safe and damage-free installation, please note the following:

i.Unloading point: Machine and spares should be unloaded at a covered, rain-free, dust-free area.

ii.Storage: Machine and spares must be stored in a secure, dry, and dust-free environment.

iii.Installation site: A roof-top shed with crane facility is required for loading/unloading pipes and smooth operation.

iv.Shop floor maintenance: Ensure clear access and sufficient space for machine installation and future maintenance.

Why Choose us?

- 35+ years company. Same business. Same team.

- Pioneer in Plasma Technology. 100% in-house products

- Indian company. Assured service & express spares

- Standard machines. High quality products.

- Automation, variety of accessories & innovation

- Productivity & efficiency improvement tools

- Very good payment, delivery & warranty terms.

Enquire / Book this machine NOW and claim an instant Rs 25,000/- discount / voucher. Just leave your contact in below form and get an instant email with Product Brochure, Company Profile, Offer & references from FABEEE (industry association) or fix google meet with our team & more!

You can purchase this machine on an outright basis or we in partnership with FABEEE can help you raise funds (not from bank, no CIBIL-CMR required) not only for the machine, but also for raw material, or you can also consider to lease this machine with buy back / sell back options.