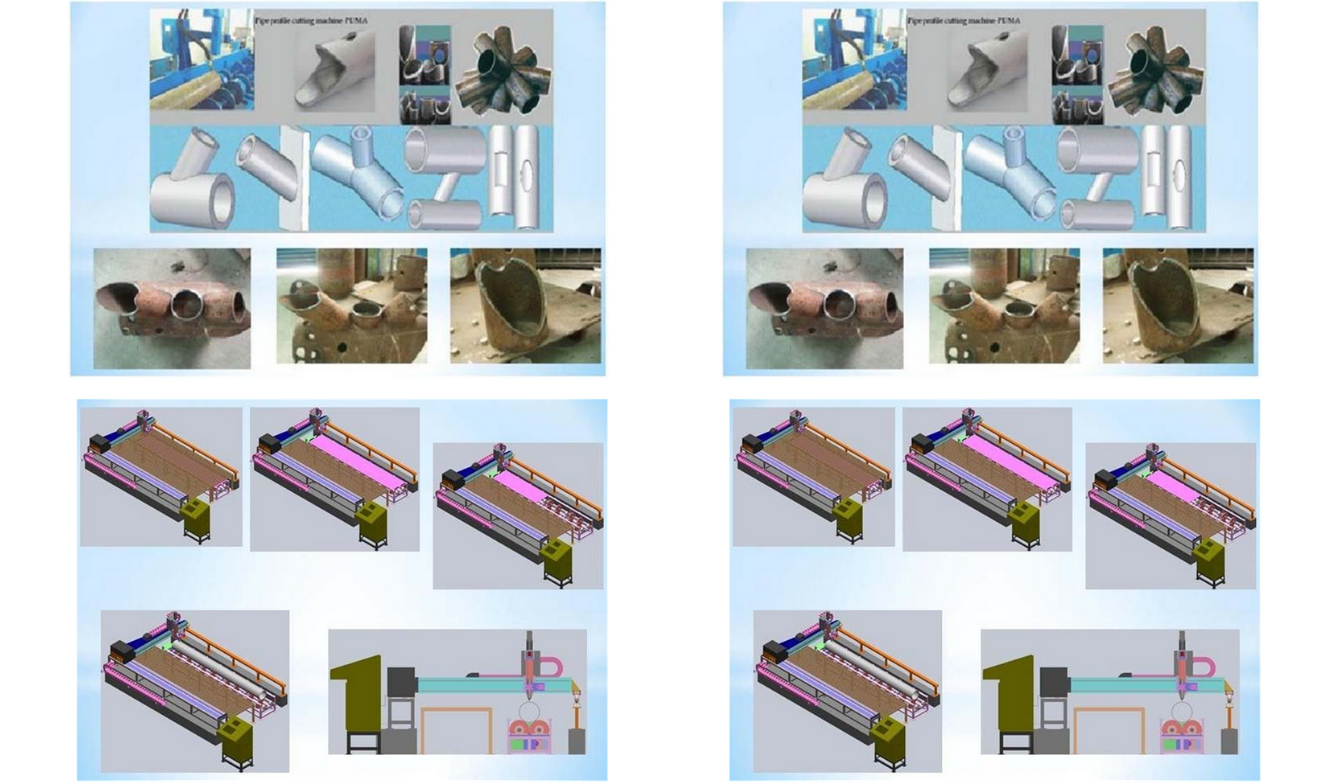

CUMA

Cuma is a miniature type CNC Pipe Profile cutting Machine used for profile cutting of pipes of diameter 50-300 mm (customisable), wall thickness 5-10 mm, pipe length of upto 3000 mm (typically asked by customers). Customers typically buy this machine to cut Piercing 16 mm, edge cutting of 25 mm with Plasma power source (125 amps) and 5-150 mm cutting capacity with OxyFuel. We manufacture higher amps power sources too which drastically offers higher cutting / piercing capacities. Power source (amperage) selection depends on cutting capacities required by customers.

Standard system consists of following:

1. 3 axis (X,Y,Z) machine with independent AC servo drives. Rotary gearbox for X axis, Rack & pinion for Y axis and Precision ball screw for Z axis offering rapid speed of upto 12 mtrs / min

2. Working area 3000 x 1500 mm (machine area 4000x2800 mm) (customisable) along with controller (Flangling or equivalent), hardware’s, motors drives, software & drag chain for cables etc. without cutting bed.

3. Oxy-fuel cutting torch with capacitive auto height controller attachment for the above & Auto Torch Igniter.

4. Plasma cutting attachment for CNC with Initial Height Sensing & Auto Height Controller model PMT.

5. 125 amps Hybrid technology Based Plasma power source Model HyCUT 125 (Air Cooled) ready for interface with CNC Controller with Air Cooled Torch OF suitable length of cable.

6. Installation, Commissioning of the CNC system and Training by our engineer to the nominated personnel at site for a period of 4 days maximum.

7. Necessary items like tools, tackles, crane, fork lifts, etc. are provided by the customer at site.

8. Foundation drawings are provided by us to the customer. Civil work and labor required for the installation is provided by the customer. Cutting bed to be fabricated by the customer based on drawings given by Technocrats

9. Structure of machine is Hardened and ground rail, specially designed guides, MS Frame

Critical items and make:

| Sr. no | Description | Make |

| 1 | Rack | KHK |

| 2 | Pinion | KHK |

| 3 | LM guides | Hiwin |

| 4 | Gearbox | Apex |

| 5 | Controller | Flangling or equivalent |

| 6 | Servomotor & drive | Panasonic or equivalent |

| 7 | Arc voltage torch height control | Technocrats |

| 8 | Plasma power source | Technocrats |

| 9 | Capacitive Height Controller | HYD |

| 10 | Oxy Fuel Torch | Longteng / Harris / TANAKA |

| 11 | Limit switches | Teknic |

| 12 | Relay card | Omron |

| 13 | SMPS | Meanwell |

| 14 | Cables | Avocab |

| 15 | Relays | Omron/ PLA |

| 16 | Cable Drag chains | IGUS/ Teknic |

| 17 | Nesting software | Kartik CAD/CAM |

Plasma source details –

| Plasma source type | IGBT type |

| Model | HyCUT 125 |

| Current range | 10 – 125 amps |

| Maximum output power | 20 kW |

| Torch cooling | Air cooled |

| Cutting capacity | Piercing – 16 mm Edge cutting – 25 mm |

Why Choose us?

- 35+ years company. Same business. Same team.

- Pioneer in Plasma Technology. 100% in-house products

- Indian company. Assured service & express spares

- Standard machines. High quality products.

- Automation, variety of accessories & innovation

- Productivity & efficiency improvement tools

- Very good payment, delivery & warranty terms.

Enquire / Book this machine NOW and claim an instant Rs 25,000/- discount / voucher. Just leave your contact in below form and get an instant email with Product Brochure, Company Profile, Offer & references from FABEEE (industry association) or fix google meet with our team & more!

You can purchase this machine on an outright basis or we in partnership with FABEEE can help you raise funds (not from bank, no CIBIL-CMR required) not only for the machine, but also for raw material, or you can also consider to lease this machine with buy back / sell back options.